Services

Mass Transfer Internals

PROCESS EQUIPMENT DESIGN:

Process Design provides the necessary data to select proper tower internals for separation, & mixing application. It is require for understating of the purpose of separation or mixing.

It is essential to know the feed composition and required temperature & pressure of the process. GDT also provides designs for our all products & as per our clients requirements. We have excellent team for design of static mixer, column internals, Distillation column, reactors & agitators, mist eliminators, etc, for efficient result & purity of product.

Our first prior concern is to provide high efficient mass transfer rate through our well designed mass transfer internals. GDT offers wide range of packings with great quality and sustainability.

1. Packings: GDT provides varieties of packings with customisation of diffrant sizes and shapes

2. Column internals: Column internals are specially designed for application of distribution, support, collection of fluid throughout the column operation. They are generally made-up of process favourable materials.

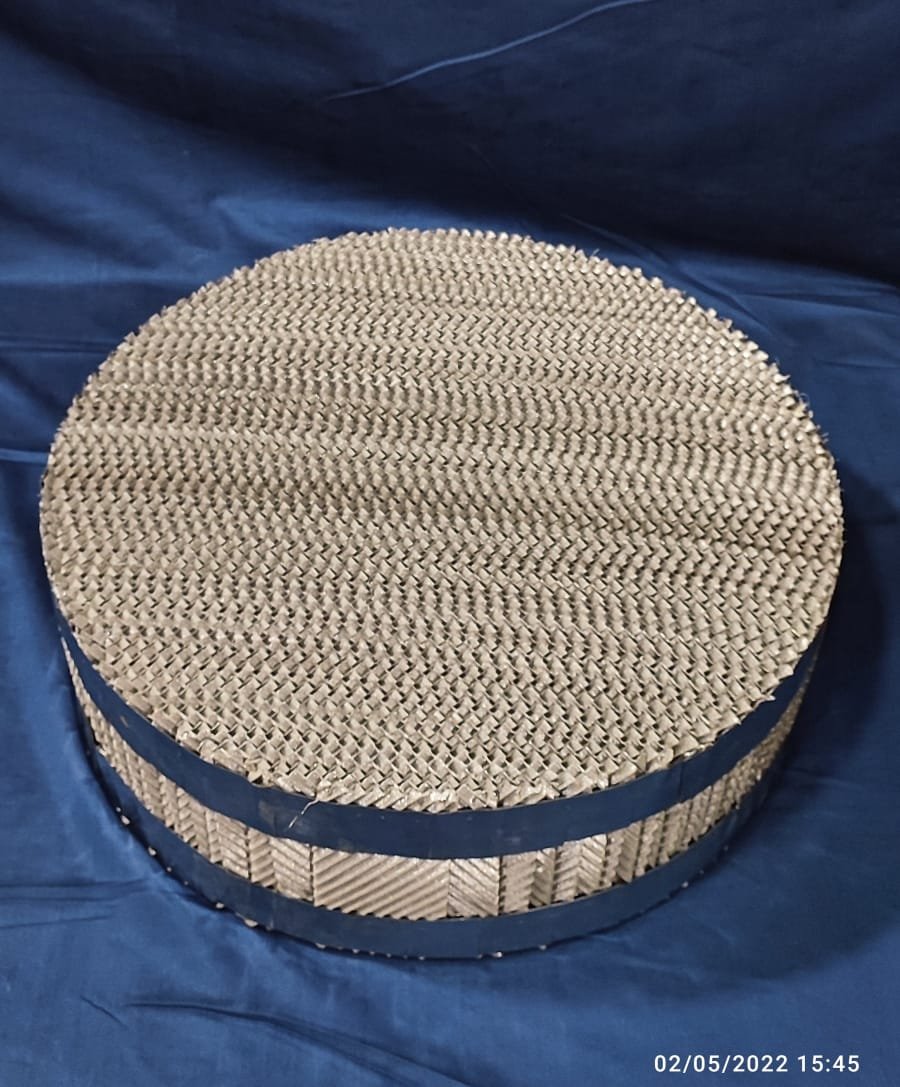

STRUCTURED PACKING :

Structured Packing is excellent for applications that require lower pressure drop, a large number of theoretical stages, and small packed bed heights.

Types of structured packing:

1. GDT- High Perfomance packing

2. GDT- Wire mesh packing

3. GDT- Ceramic structured packing

RANDOM PACKING:

Process advantage of RANDOM PACKIING :

1. Reduce liquid holdup in the column.

2. Increase the capacity & efficiency compared to trays.

3. Reduce pressure drop through the column.